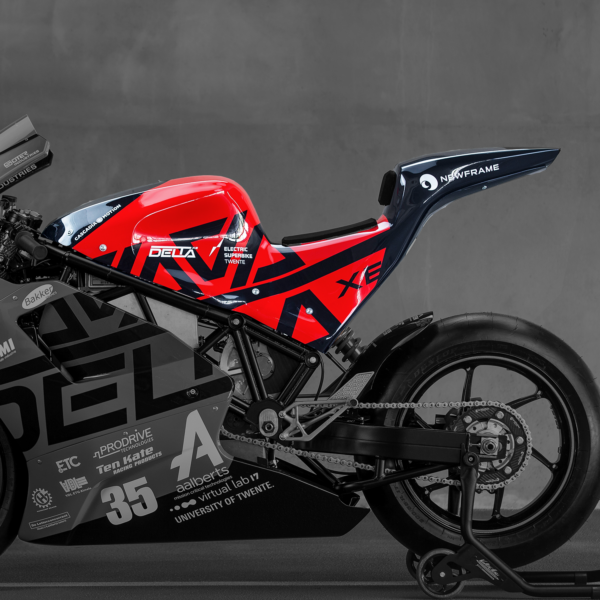

The Delta XE is enveloped by bodywork that gives the bike a neat look and enhances the aerodynamic properties of the bike. The top part of the bodywork is called the subframe. The subframe is part of the frame, as it is mounted directly to it. The subframe should be able to handle the load of the rider while the motorcycle is on the track.

Currently, the subframe of the Delta is made out of a carbon fibre composite. In order to fabricate such a part, a mould is needed to shape the carbon sheets. A total of ten layers of carbon is used to give the subframe the strength and low weight it needs. A type of foam is used in the middle of these layers to enhance the strength.

The subframe is designed to protect the components that are located beneath it, such as the motor controller, from water and debris. Furthermore, it gives the rider a place to put his legs on, allowing him to clamp around the bike and maintain stability. Unfortunately, the space that should be occupied by the motor controller was limited by a torsion bar in the front of the motorcycle. This bar prevented the motor controller to be located in the front and instead of being placed underneath the bar, it was moved further back. However, the motor controller proved to be larger than expected, interfering with the subframe from the inside. This problem was solved by taking a small amount of material out of the subframe at the locations where the motor controller comes in contact with the subframe. Furthermore, the frame warped after welding, causing the mounting tabs for the subframe to be slightly misaligned. The subframe mounting holes do not match the mounting tabs of the frame as a result. This can be solved by using the current subframe as a template for the new subframe in order to determine the new locations of the mounting holes.

The fact that the current subframe has some imperfections allows us to tweak the design, making it better as a result. Firstly, the new design can be lighter. Fewer carbon sheets can be used to maintain sufficient strength, while reducing the weight significantly. Secondly, the subframe requires slightly more width at the locations where the motor controller interferes with the subframe. The mould of the current subframe has already been manufactured, and creating a new mould is rather expensive. This means that for a new subframe, with the changes mentioned above, the mould needs to be changed accordingly. It can be achieved by editing the mould file with CAD software after which a CNC router is able to determine toolpaths and adjust the mould as desired. This way the new mould can be used to manufacture a new subframe. Ultimately, this should give us a subframe that is both lighter, easier to attach and a better fit.

– Stijn van der Veen