The insulation monitoring device, or IMD for short, is an essential part in the system that ensures the bike is safe. It measures the insulation resistance between High-Voltage conductors in our electrical drive system and the reference earth, the chassis. If this resistance is too low, there is a chance that if someone were to touch the frame, they would get electrocuted. To prevent this, the high voltage system must shut off in case of insufficient insulation.

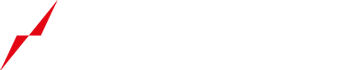

The IMD we use is the Bender IR155-3204. On the DELTA-XE, the IMD is placed inside the battery pack. The High-Voltage measurement connectors XLA+ and XLA- are connected to our battery pack positive and ground respectively. The IMD requires two separate reference earth points. One of these points is connected to the inside of the battery pack casing. The other point is attached to the frame. The IMD outputs an ‘IMD_OK’ signal. This signal can either be low or high. The IMD_OK signal is received by the chip on the High Voltage Control Board (HVCB) and some relays. The relays are in series with the signal wire to the high voltage relays. When the IMD_OK signal is low, these relays are open thus preventing the HV relays from closing.

In case of a fault, the IMD_OK signal will drop low. The Bender IR155-3204 react to three cases:

1. When the insulation measurement is below the required value

2. If an undervoltage is detected in the high voltage battery pack

3. If a device fault occurs

-Jord Boersma